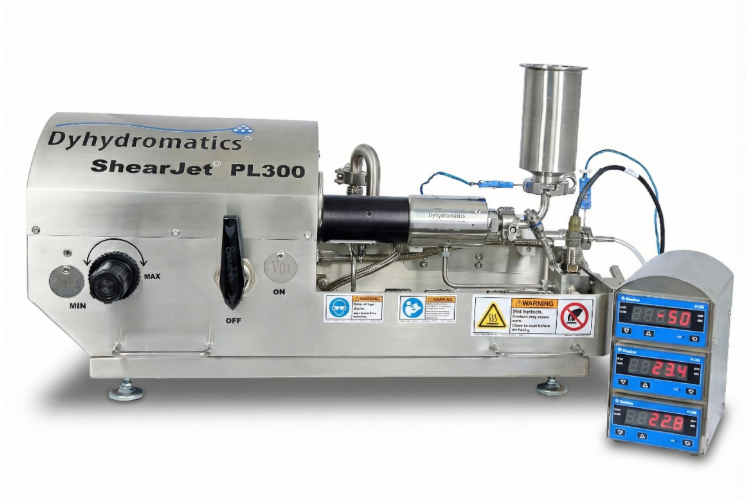

PL300Information

Tight Distributions of Formulations.

The ShearJet® PL300 processor is a small pneumatic driven processor which is available in non-pharma and pharma versions. Both processors generate pressure up to 23,000 psi with a stroke volume of 6 mL. The non-pharma model handles a sample size of 45 mL and up. The pharma model handles a sample size of 70 mL and up. Flow rates range from 300 to 450 mL/min. Our Simple feed jacketed heat exchanger (non-pharma) and tube and shell heat exchanger (pharma) require a chiller. Quick disconnect cooling water connections make setup easy. Our multiplier pump is equipped with a ceramic plunger and view port isolator. The Reaction Chamber® Module set will process products consistently and repetitively.

PL300Non-Pharma

- Sample size: 50 mL – 2 L plus

- Pressure: 1 – 23 Kpsi (69 – 1586 bar)

- Stroke: 6 mL

- Output: 350 – 450 mL/min at 23 Kpsi (subject to Reaction Chamber® type)

- Power: pneumatic air motor (15 hp compressor, 120 psi, 57 scfm, and/or air tanks required)

- Dimensions: 17″ x 32.3″ x 16.7″ (432 x 820 x 424 mm)

- Application: Nanoemulsions, nanodispersions, nanosuspensions, liposomes, polysaccharides, deagglomeration, encapsulation, cell rupture

- Features: Diamond Reaction Chamber®, back pressure Reaction Chamber® module, 400 mL reservoir, simple feed jacketed helical heat exchanger, ceramic plunger, dual gauge for air and process pressure, tools and spares.

- Optional reservoirs: Simple Feed 1 Liter and up

PL300PHPharma

- Sample size: 70 mL

- Pressure: 1 – 23 Kpsi (69 – 1586 bar)

- Stroke: 6 mL

- Output: 350 – 450 mL/min at 23 Kpsi

- Pharma grade parts

- Power: pneumatic air motor (15 hp compressor, 120 psi, 57 scfm, and/or air tanks required)

- Dimensions: 18″ x 37″ x 17″ (457 x 940 x 432 mm)

- Application: Nanoemulsions, nanodispersions, nanosuspensions, liposomes, polysaccharides, de-agglomeration, encapsulation, cell rupture

- Features: Diamond Reaction Chamber® Module, back pressure Reaction Chamber®, 400 mL reservoir, simple feed tube and shell pharma heat exchanger, dual gauge for air and product pressure, USP class VI seals, o-rings, gaskets, EP and passivation of high pressure connections, pressure transducer, display with retransmission, ceramic plunger, tools & spares.

- Optional reservoirs: Simple Feed 1 Liter and up

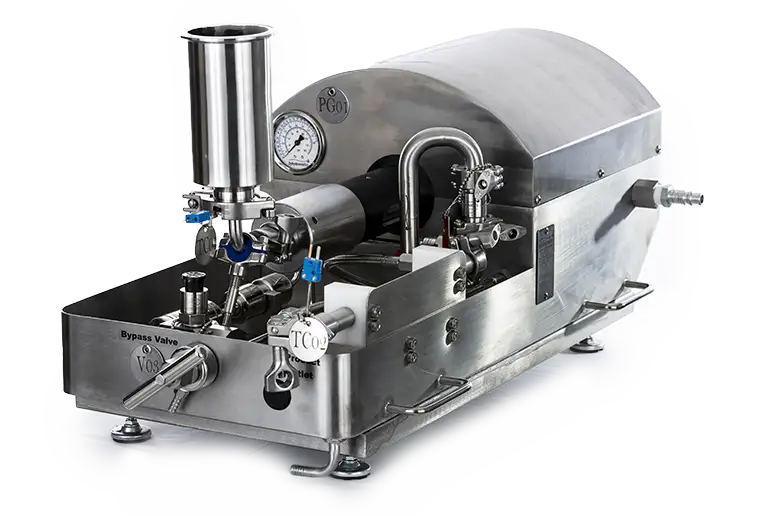

NEW HP350 V2Information

For R&D/Pre-Pilot Scale Processing

The ShearJet® HP350 V2 series electric-hydraulic processor operates with a single multiplier pump which processes 80 mL to 50 L and higher sample sizes and high flow rates in distinct passes or continuous runs. Its reliable and robust design makes the HP350 V2 model a, viable option for R&D and pre-pilot scale applications. Its integrated HMI with data acquisition capabilities is very user friendly and easy to read. Its small compact design and casters, makes transport between lab suites seamless.

Specifications:

- Sample size* ml = 80

- Pressure Kpsi (max.) 30

- Pressure bar (max.) 2068

- Flow rate ** ml/min 300-450

- Electric Hydraulic 5 HP, 60 Hz, 230/460,

- 12.4/6.2 Amps; (50Hz 190/380 VAC, 15.2/7.6 Amps (on request)

- Operating time: System can run from seconds to hours

HP 350 V2 SeriesStandard

- 1 Liter stainless steel reservoir

- Ceramic Plunger

- Flush diaphragm pressure transducer

- Reaction Chamber® Modules

- 2 RTDs

- Product heat exchanger tube and shell

- Touch screen HMI with advance features

- FAT/SAT

HP 350 V2 SeriesPharma Standard

- 1 Liter stainless steel reservoir

- Ceramic Plunger

- Flush diaphragm pressure transducer

- Electropolish & Passivation

- USP Class VI plastic and elastomers with certification

- Reaction Chamber® Modules

- 2 RTDs

- Product heat exchanger tube and shell

- Touch screen HMI with advance features

- FAT/SAT

- IQOQ

HP 350 V2 SeriesPharma Premium

- 1 Liter stainless steel reservoir

- Ceramic Plunger

- Flush diaphragm pressure transducer

- Electropolish & Passivation

- USP Class VI plastic and elastomers with certification

- Reaction Chamber® Modules

- CIP bypass product heat exchanger

- 2 RTDs

- Product heat exchanger tube and shell

- Touch screen HMI with advance features

- Data recording enabling easy 21 CFR Part 11 compliance

- FAT/SAT

- IQOQ