December 18, 2025

High-Shear Homogenizers & Expert Services

Featuring the New ShearJet® HL60 V2

(Now Available in 110 VAC)

Learn More

Dyhydromatics, LLC designs and manufactures laboratory through production high pressure homogenizers used to reduce particles to the nano level. Our specially designed ShearJet® processors, assembled and tested in Maynard, Massachusetts, achieve a repeatable, evenly distributed, uniform particle down to the nano level that is unmatched. Unlike the competition, we are a full package company offering superior machines, parts, and services.

We are the masters when it comes to customer satisfaction.

Equipment

Medium Volume Homogenizers

Pneumatic laboratory benchtop and electric hydraulic high shear homogenizers

Feed & Skid Systems

Working with our partner, we can design a complete turnkey system to reduce processing time, lower dead volumes, and increase product recovery.

Our Services

Equipment Service & Consultation

Over 30 years of servicing all brands of high shear processors and lab equipment.

Proof of Concept

We process your product with Dyhydromatics technology and provide a complimentary evaluation report of the results.

Process Development

With experience in over 1500 formulations over the years, we can address even the most challenging applications to help you determine optimal process parameters for your formulation.

News, Articles, & Case Studies

Markets that Benefit from Our High Shear Processing.

Pharmaceutical

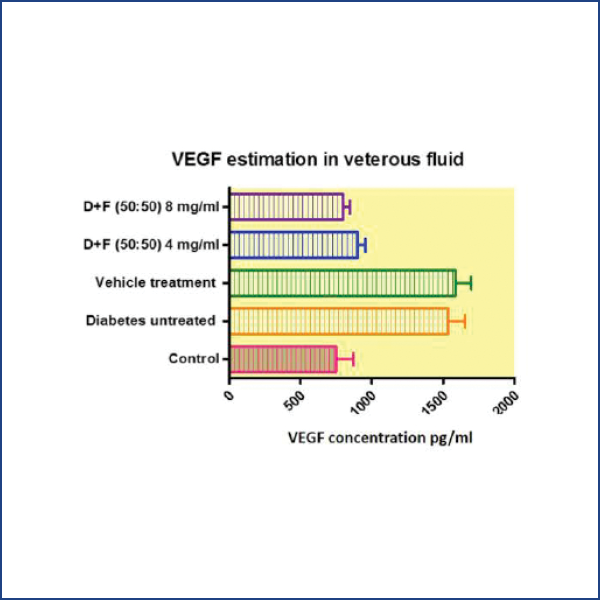

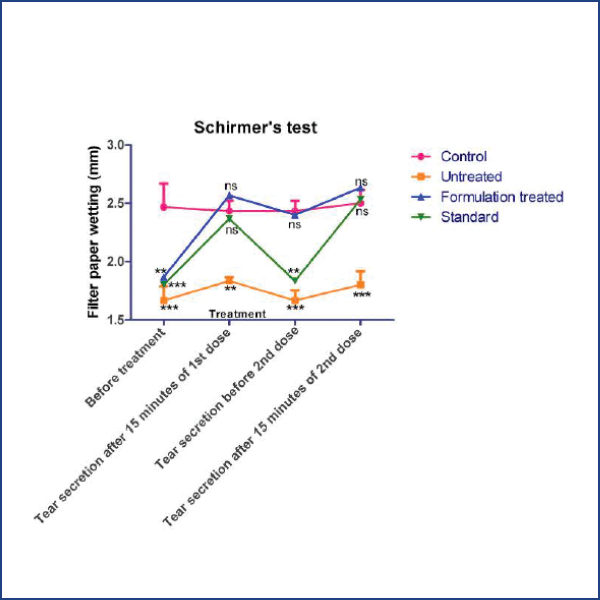

Consistent uniform particle size reduction (to nano sizes) allows the pharmaceutical industry to create far more stable products with targeted delivery.

Biotechnology

Gentle, productive cell disruption is vital to the biotech industry to study and use the intercellular materials. Demand for these materials is on the increase as they are used in other industries as well, including pharmaceutical, agriculture, and bio-services.

Chemical

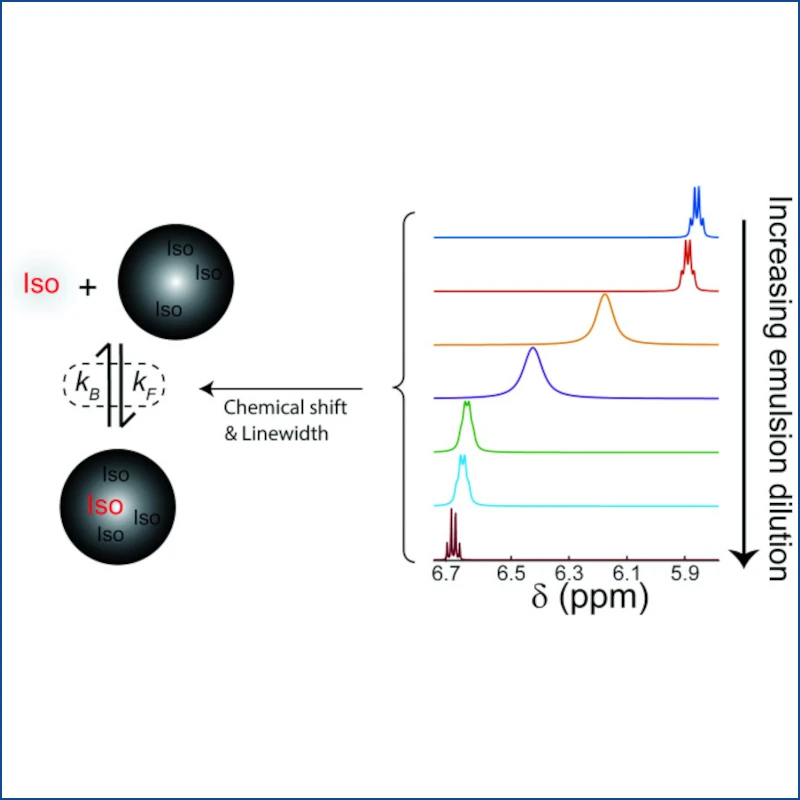

Exemplary nanoemulsions, liposomes, and biochemical cell disruption within the chemical industry lead to products with longer shelf-life and stable formulations.

Personal Care / Cosmeceuticals

Nanotechnology allows cosmetics to deliver benefits to a targeted depth, and to eliminate unwanted side affects, like the white coating in sunscreen.

Food / Nutraceuticals

Much advancement has come to fruition in the past decade incorporating nanoemulsions, nanodispersions and encapsulation in the food and beverage industries. These have allowed for targeted delivery of bioactives, longer shelf life, enhanced flavor/aroma, and improved mouth-feel with fat reduction.

Cannabis

While cannabis nanoparticle research is in its infancy, high shear processing is a superior method of increasing bioavailability, and achieving stable formulations.

What They're Saying About Dyhydromatics

Mecozzi Lab Employees

University of Wisconsin-Madison

The best part of working with Dyhydromatics is their customer service. The employees not only have a broad, technical knowledge base but they are also easy to reach over the phone or email and provide unprecedented assistance.

Nelson Landrau

Laundrau Scientific Innovations

I find the ShearJet processor to work more efficiently than the competitive fixed-geometry processor because I can process more material in less time. What took me 3 passes before, I can achieve in one pass on the ShearJet processor.

J. Kendall Killgore

Director, Product Development

Kereos, Inc.

Fortunately for our company, that’s where Dyhydromatics came in. T Field Service Technician did everything – in just a few hours he carried out a complete preventive maintenance on our purchase and then took the time to instruct me on its operation.